In some cases, you may decide that it easier to use a division board to create one continuous seam across the deck surface. Applying decking diagonally can often reduce or eliminate the number of butt joists on decks that are over 20’ wide. Depending on the size and shape of your deck design, this may be easy to accomplish without any effort, or you may have to make some adjustments. Butt joints tend to separate and warp as the decking material weathers. It is always best to try to avoid seams on your deck surface. Hollow decking products will leave open ends that aren’t attractive and can collect dirt, leaves, etc. Most hollow decking products sell end caps that can close the ends. Another method involves installing a racetrack or picture frame pattern perimeter to cover the open ends. We recommend using reverse thread screws when face-screwing composite decking to eliminate mushrooming. Mushrooming occurs when a standard bugle head screw pulls some composite material above the surface during installation. The resulting raised bump isn’t very attractive. You can also use a hammer to level the surface.

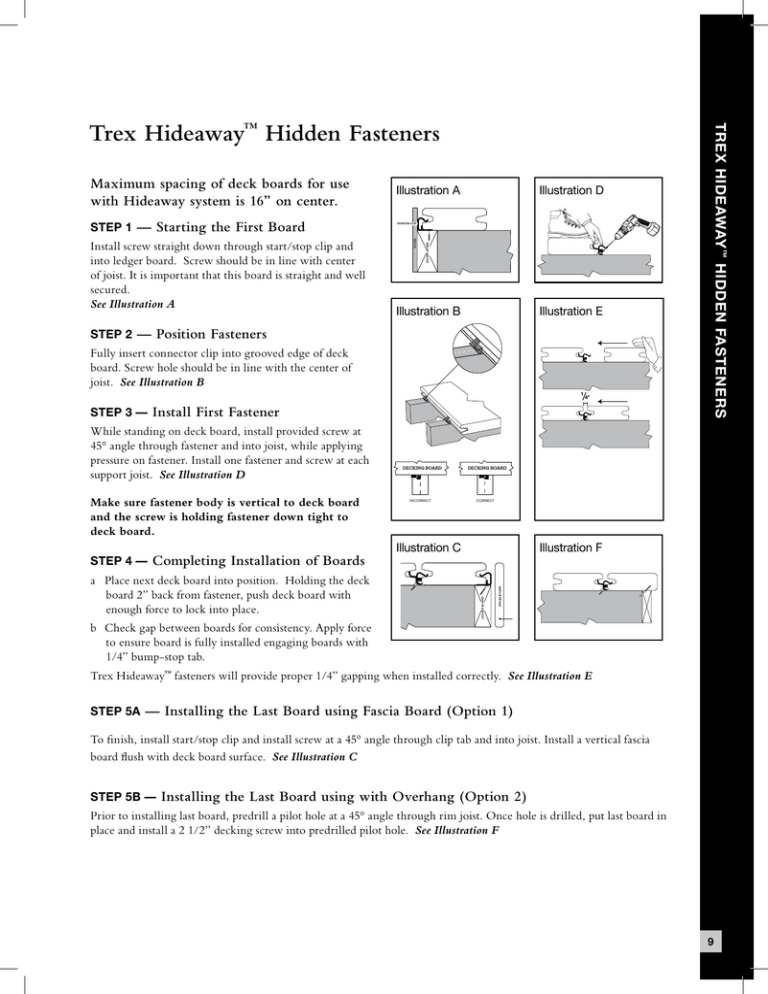

Some composite decking materials are designed to be installed with hidden fasteners. These clip systems generally are screwed into to the deck frame across each joist and fit tightly into a cavity running down the side of the boards. In most climates, temperatures fluctuate enough to cause an issue with how the decking is spaced from summer to winter. Composite decking tends to grow and shrink across the length of the boards as it heats and cools. Proper spacing will allow some movement without buckling. It is very important to follow the manufacturer’s instructions when installing composite decking material. Thermal expansion is always something to be aware of when dealing with plastics.

0 kommentar(er)

0 kommentar(er)